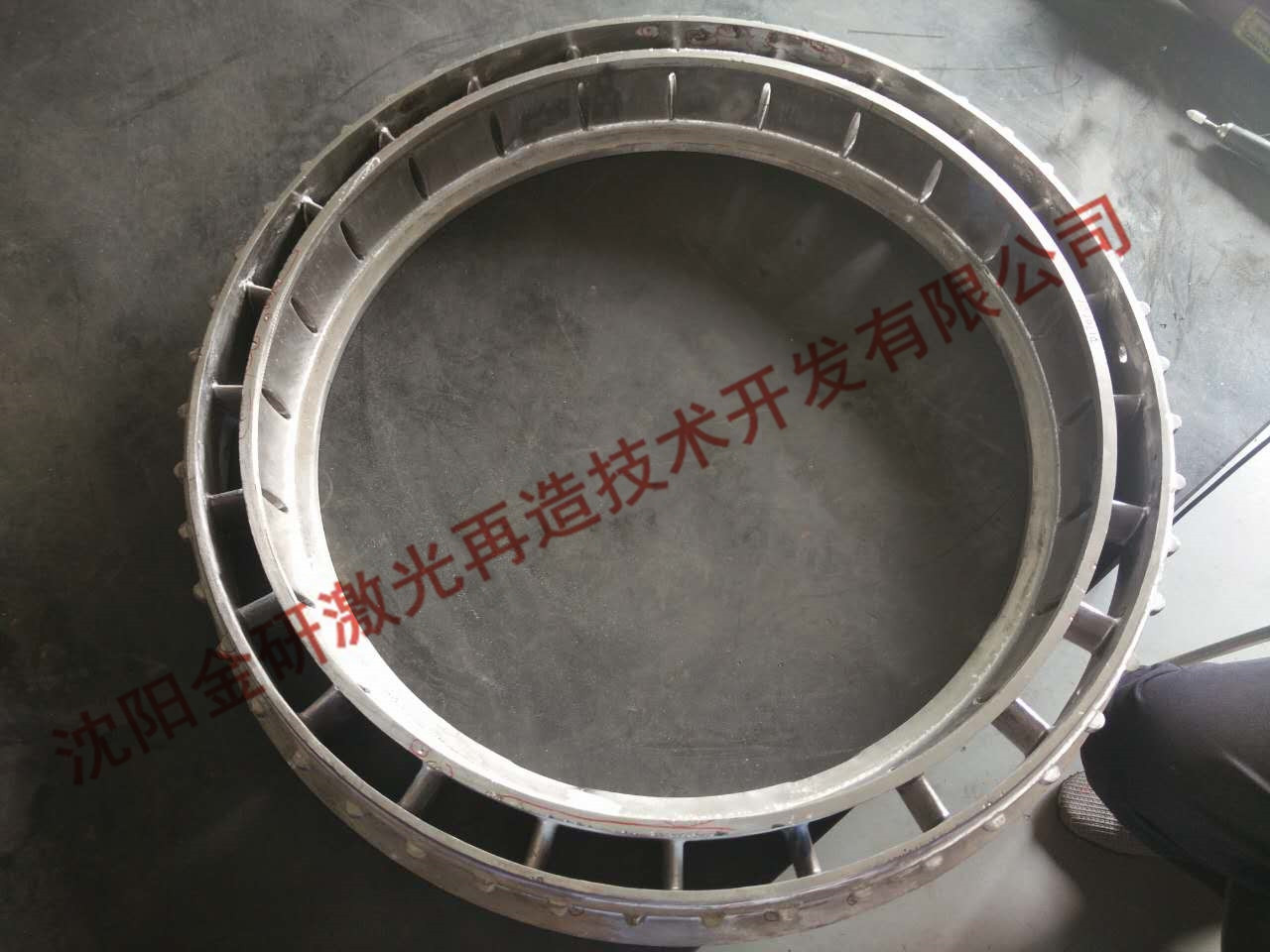

Recently, Jinyan Laser received two Ti3AL disks that need to be repaired from the Institute of Chinese Academy of Sciences.

The main material of Ti3AL is titanium alloy. Due to the material itself, it is mainly used in aerospace engines and other fields. The customer requires that the heat-affected zone and thermal deformation are small during the processing, and the metal properties inside the substrate are not changed.

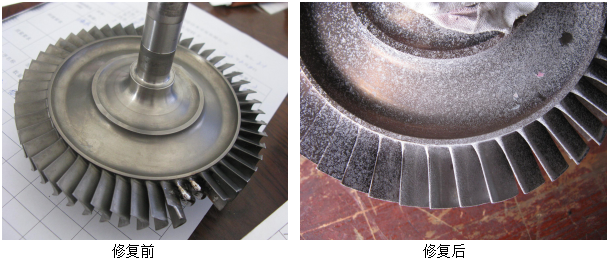

Shenyang Jinyan Laser adopts the process method of alloy single-sided welding and double-sided forming, which can achieve:

1. Repair other non-failure parts that are not on the machine during processing

2. The repair process does not cause secondary damage to the workpiece, such as deformation and damage. (including substrate return, tempering or requenching, hot cracking, etc.)

The repaired area and the workpiece matrix are metallurgically combined, the strength of the repaired area can reach 85% of the original material, and the wear resistance, corrosion resistance and erosion resistance can be significantly higher than the original workpiece material, which can extend the workpiece after repair. Re-use life.

Other project cases of Jinyan Laser:

Shenyang Jinyan Laser is the most ideal unit for non-destructive and reliable repair of all aircraft power units, whether from repairing special materials, heat treatment and stress modulation in the repair area, and supplementary coating protection for repair machines.

Language

Language  中文简体

中文简体 English

English

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province.

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province. Phone:13898848281

Phone:13898848281 Landline:024-25799905

Landline:024-25799905 Fax:024-25799905

Fax:024-25799905 E-mail:jyjg2018@163.com

E-mail:jyjg2018@163.com