original:

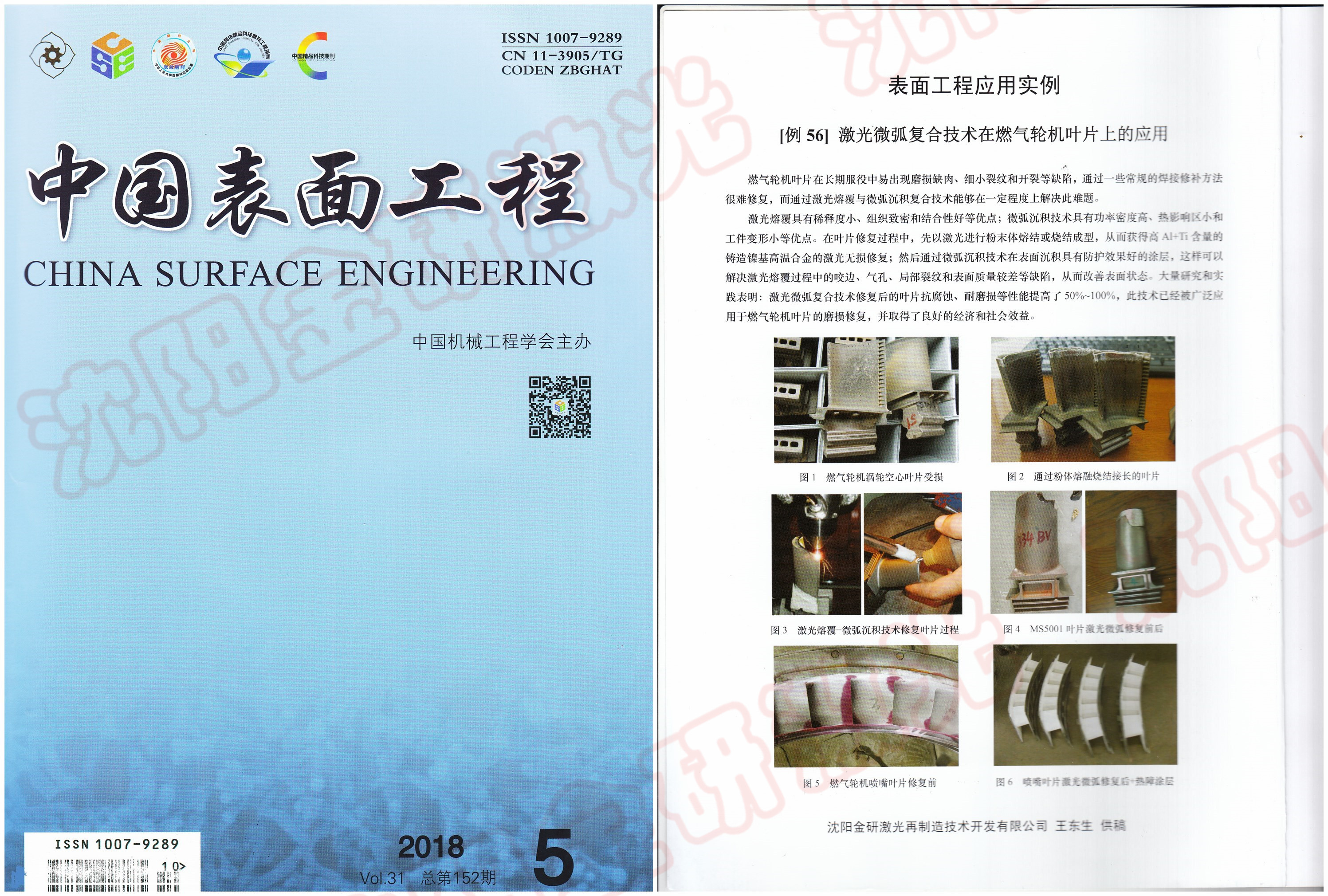

Gas turbine blades are prone to wear and tear, small cracks and cracks during long-term service. It is difficult to repair through some conventional repair welding methods. However, laser cladding and micro-arc deposition repair technology can solve this problem to a certain extent. problem.

Laser cladding has the advantages of small dilution, dense organization and good bonding; micro-arc deposition technology has the advantages of high power density, small heat-affected zone and small deformation of workpiece. In the process of blade repair, advanced laser is used for powder sintering or sintering to obtain laser non-destructive repair of cast nickel-based superalloys with high Al Ti content; then micro-arc deposition technology is used to deposit on the surface with good protective effect Coating, which can solve defects such as undercuts, pores, local cracks and poor surface quality during the laser cladding process, thereby improving the surface condition. A large number of studies and practices have shown that the blades repaired by laser micro-arc composite technology have improved corrosion resistance and wear resistance by 50%-100%. This technology has been widely used in the wear repair of gas turbine blades, and has achieved good results. economic and social benefits.

Jinyan Laser is committed to the effective reuse of damage and failure of aero-engine parts, ground gas turbine hot-end parts, petrochemical equipment, metallurgical coal equipment, energy power equipment and components. We sincerely invite people from all walks of life to cooperate with our company, we will provide you with a complete laser repair solution!

Company address: A-1, No. 13, South 23rd Road, Economic and Technological Development Zone, Shenyang City, Liaoning Province

Contact number: 024-25799906

Company website: www.wmclaser.com

Language

Language  中文简体

中文简体 English

English

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province.

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province. Phone:13898848281

Phone:13898848281 Landline:024-25799905

Landline:024-25799905 Fax:024-25799905

Fax:024-25799905 E-mail:jyjg2018@163.com

E-mail:jyjg2018@163.com