The principle of laser cladding

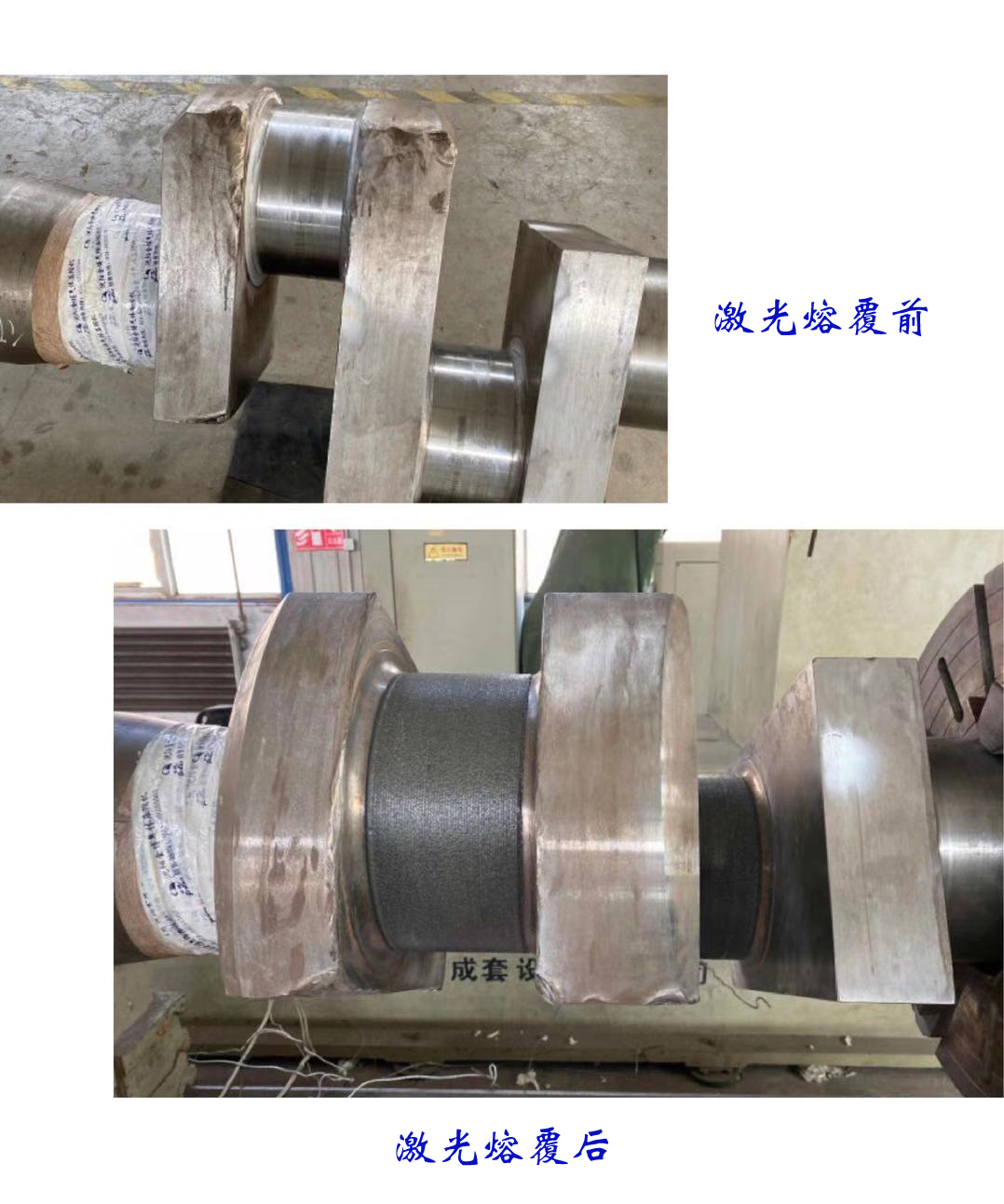

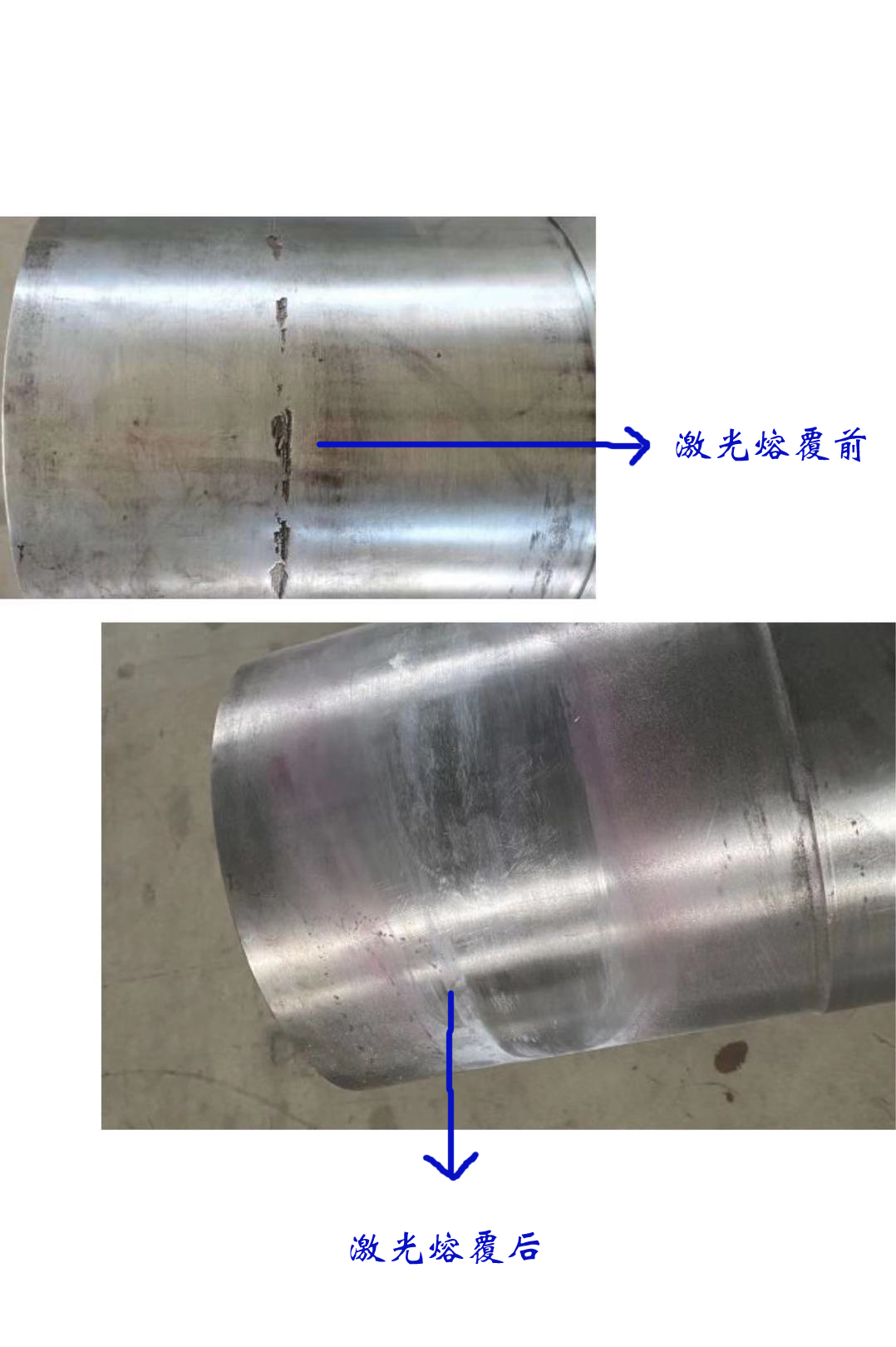

Laser cladding is the use of high-energy laser beam irradiation, through rapid melting, expansion and solidification, cladding a layer of materials with special physical, chemical or mechanical properties on the surface of the substrate to form a new composite material, which has made up for the matrix. The lack of high performance can give full play to the advantages of the two and overcome the shortcomings of each other.

According to the working conditions of the workpiece, metal or non-metal of various (design) components is clad to prepare a surface coating with heat resistance, corrosion resistance, wear resistance, oxidation resistance, fatigue resistance or optical, electrical and magnetic characteristics. Through laser cladding, a layer of high melting point alloy can be clad on the low melting point material, and the surface of non-phase change materials (AI, Cu, Ni, etc.) and non-metallic materials can also be strengthened.

Advantages of laser cladding:

(1) The cladding layer has fine grains and dense structure, so India is generally higher, and its wear resistance and corrosion resistance are also better.

(2) The dilution rate of the cladding layer is low. Due to the short laser action time, the melting amount of the substrate is small, and the dilution rate of the cladding layer is low (generally only 5%-8%), so the cladding layer can be thinned. In this case, the required composition and properties can be obtained, and the expensive melting layer material can be saved.

(3) The heat-affected zone of laser cladding is small, the deformation of the workpiece is small, and the yield of cladding is high.

(4) The laser cladding process is easy to achieve automatic production, and the quality of the coating is stable. For example, the thickness of the cladding can be continuously adjusted during the cladding process, which is difficult to achieve in other processes.

Due to the above advantages of laser cladding, it has broad application prospects in aerospace and even civil product industry, and has become a hot spot of research and development in the field of materials today.

Shenyang Jinyan Laser Remanufacturing Technology Development Co., Ltd. was established in 2006. It has been focusing on laser repair and remanufacturing. It has a mature technology and a complete set of corresponding methods, including pretreatment of damaged areas and analysis of the origin, mechanism control of irradiation, Finishing treatment, non-destructive testing, tissue adjustment, stress state adjustment, protective coating, etc., to achieve non-destructive remanufacturing of workpieces, and have relatively complete comprehensive supporting equipment capabilities. Welcome people of insight to cooperate and achieve a win-win situation!

Language

Language  中文简体

中文简体 English

English

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province.

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province. Phone:13898848281

Phone:13898848281 Landline:024-25799905

Landline:024-25799905 Fax:024-25799905

Fax:024-25799905 E-mail:jyjg2018@163.com

E-mail:jyjg2018@163.com