You may only know that laser welding machines and fiber laser marking machines are widely used in the current aerospace field, providing a lot of convenience for the processing and production in the aerospace field. In fact, the application of laser cutting machine in the aerospace field is also very extensive, especially in the current field of aero-engine.

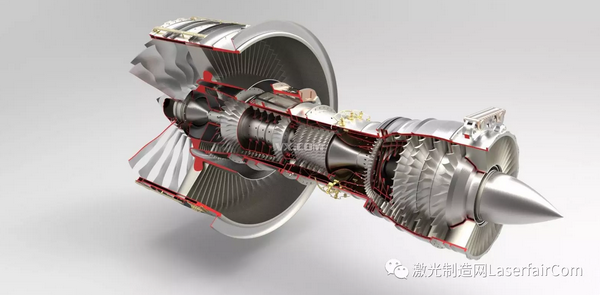

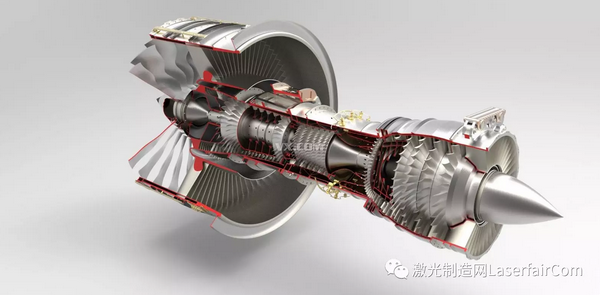

As a top-manufactured aero-engine, it is a highly complex and precise thermodynamic machine. Each manufacturing process is extremely demanding and requires a wide variety of materials. The high-temperature components in it not only need to withstand scorching high temperatures, but also need to withstand high temperatures. Strong air pressure, the slightest error directly leads to the failure of the entire aircraft. Now the design and manufacture of aero-engines are very complex, covering tens of thousands to hundreds of thousands of small parts, and a large number of current titanium alloys, high-temperature gold, stainless steel and other non-metal special coatings are used. These materials not only have high specific hardness , brittle, but also has the characteristics of high melting point and low thermal conductivity. For example, the turbine blades inside are not only special in shape, but also have the characteristics of high temperature resistance. If the conventional processing method is used, the operation is not only complicated, but also the process requirements are difficult to achieve. Therefore, it is necessary to use the current high-tech means--- Laser technology laser cutting machine.

As for the current laser technology, with the continuous maturity of technical means and the development of related industries, the application of laser industrial technology in the aerospace field is becoming more and more extensive. As an important technical process of laser application, laser cutting technology is widely used in the aerospace field, especially in the current aero-engine field.

Because laser cutting has the characteristics of high precision, fast processing speed, small thermal effect, and no mechanical effect, it has applications in many aspects of aero-engine manufacturing, from the air intake to the exhaust nozzle of the current aero-engine. Applied to the current laser cutting technology. The use of current laser cutting technology has solved many problems such as cutting of difficult-to-machine materials for aero-engines, efficient processing of large-scale thin-walled group holes, high-precision cutting of blade-shaped holes of parts, and processing of special surface parts, which has effectively promoted the current aviation vehicles. , to develop in the direction of high performance, light weight, long life, short cycle, low cost, etc., which has added a lot of impetus to the development of the aviation industry.

Language

Language  中文简体

中文简体 English

English

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province.

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province. Phone:13898848281

Phone:13898848281 Landline:024-25799905

Landline:024-25799905 Fax:024-25799905

Fax:024-25799905 E-mail:jyjg2018@163.com

E-mail:jyjg2018@163.com