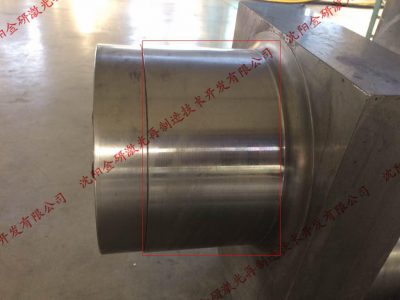

Recently, Shenyang Jinyan Laser Remanufacturing Technology Development Co., Ltd. received the BROAD 35CrMo crankshaft. Due to wear, the crankshaft had insufficient shaft diameter and could no longer be used. Our company uses the method of laser cladding to repair, and the estimated construction period is one day.

As the main rotating part of the engine, the crankshaft can take over the up and down (reciprocating) motion of the connecting rod and turn it into a cyclic (rotating) motion after the connecting rod is installed. If not maintained properly, it is very prone to wear and tear. Generally, the damaged parts of the crankshaft are mainly in the main journal and the connecting rod shaft, and due to the problem of the direction and size of the force, it is easy to cause the inner side of the connecting rod journal to be worn and become oval, so that the force of the equipment is affected. will have a big impact. Scratches and burns may also occur on the crankshaft surface. Scratches are mainly caused by unclean engine oil, in which larger hard mechanical impurities are scratched on the surface of the journal; burns on the surface of the journal are caused by burning tiles, which are mainly due to insufficient lubrication, too thin oil, and Caused by road blockage, etc.

If the crankshaft is damaged and the journal position is inclined, first of all we need to know what kind of material the crankshaft is and what effect it needs to achieve after repair, and then we can formulate a repair process card, and the surface must be oxidized before cladding. After laser cladding, the power, speed, spot size, cladding material, etc. of the laser should be fully prepared, so that the crankshaft after laser cladding can be put into normal use.

Laser cladding technology is a high-tech product in manufacturing technology, and its performance in crankshaft repair is very good. By adding a cladding material on the surface of the base material, a high-energy-density laser beam is used to clad the thin layer on the surface of the base material, without affecting the quality of the original laser cladding layer and the quality of the original coating inside the cylinder. In addition to achieving dimensional accuracy and surface roughness, the repaired shaft diameter also has to meet the tolerances of the parts, so that the use effect is the same as before.

Shenyang Jinyan Laser Remanufacturing Technology Development Co., Ltd. applies advanced laser cladding technology to reduce energy consumption, effectively utilize resources, reduce costs, fully meet customer needs, and truly maximize benefits for customers.

Language

Language  中文简体

中文简体 English

English

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province.

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province. Phone:13898848281

Phone:13898848281 Landline:024-25799905

Landline:024-25799905 Fax:024-25799905

Fax:024-25799905 E-mail:jyjg2018@163.com

E-mail:jyjg2018@163.com