Recently, Jinyan Laser repaired the TA15 titanium alloy 45 frame sent by a factory, and found a crack after coloring treatment. Our company uses cold metal transfer welding (CMD) to repair, and after ultrasonic impact, grinding, coloring and X-ray inspection, no abnormality is found, and the repair of this part is completed.

not repaired

The crack here is close to the positioning hole. In order to prevent the deformation of the positioning hole and affect the later use, special tooling is made before welding to effectively prevent secondary damage.

after repair

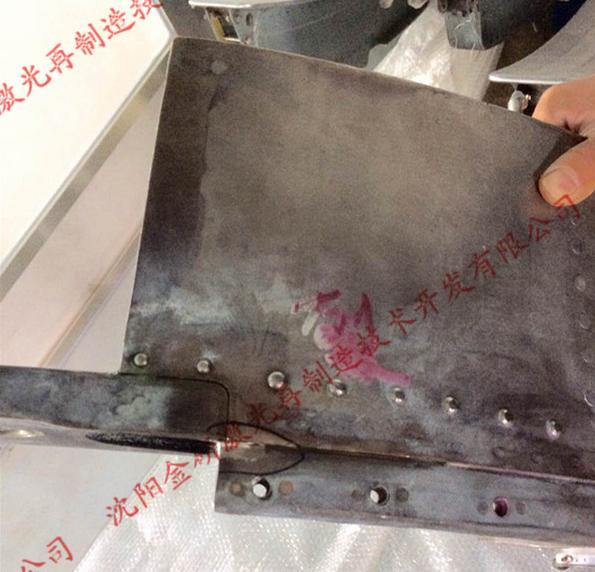

At the same time, our company received the flat-mouth transfer stage that needs to be reinforced from a military factory. A tear test is performed before welding (there is a round hole on one piece of the torn sample and a round boss on the other piece, which is a high-quality solder joint) to determine the feasibility of the process.

flat turn stage

We sincerely invite people from all walks of life to cooperate with our company, we will provide you with a complete laser repair solution!

Company address: No. 13A, No. 13, South 23rd Road, Economic and Technological Development Zone, Shenyang City, Liaoning Province

Tel: 024-25799905

Language

Language  中文简体

中文简体 English

English

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province.

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province. Phone:13898848281

Phone:13898848281 Landline:024-25799905

Landline:024-25799905 Fax:024-25799905

Fax:024-25799905 E-mail:jyjg2018@163.com

E-mail:jyjg2018@163.com