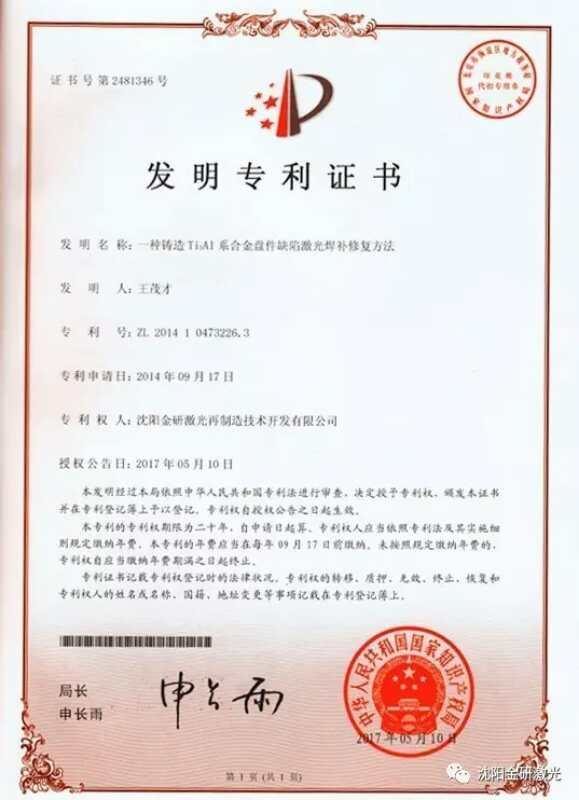

In May 2017, Jinyan Laser obtained the invention patent certificate for "a method of laser welding repairing and repairing defects of cast Ti3Al alloy disk parts". This patent is a patent project in cooperation with the titanium-aluminum compound research group of the Institute of Metal Research, Chinese Academy of Sciences.

In 2014, when the titanium-aluminum compound research group of the Institute of Metal Research of the Chinese Academy of Sciences developed the precision casting of the inner ring of the Ti3Al alloy guide vane, due to the large construction size and complex structure, the casting defects that are difficult to completely eliminate need to be repaired by repair welding to improve the yield. In the same year, the titanium-aluminum compound research group of the Institute of Metal Research, Chinese Academy of Sciences cooperated with Jinyan Laser to solve this problem.

In 2015, Jinyan Laser used this technology to repair the defects of the metal test brake blade internal environment casting, that is, the Ti3Al alloy welding repair material was directly welded to the casting area under a certain preheating temperature to eliminate defects, and then the laser beam continuously vibrated and scanned. Fusion welding is performed until the entire area is additively manufactured to a defect-free state. The repaired castings have been inspected and qualified by the Chinese Academy of Sciences Metal Research, meeting the requirements for use and meeting the requirements for use. The application of this technology has greatly improved the pass rate of the precision casting of the inner ring of the Ti3Al alloy guide vane, and the additive manufacturing effect on defects is obvious. It is a feasible additive manufacturing technology!

Language

Language  中文简体

中文简体 English

English

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province.

Address:A No.13 Twenty-third Road, South Economic and Technological Development Zone, Shenyang City, Liaoning Province. Phone:13898848281

Phone:13898848281 Landline:024-25799905

Landline:024-25799905 Fax:024-25799905

Fax:024-25799905 E-mail:jyjg2018@163.com

E-mail:jyjg2018@163.com